3D printing Muscle Car parts? At INTEGRIS we are car enthusiasts as well, and were approached with a very interesting proposition, could we 3D Print near factory correct parts for an ongoing muscle car restoration? Us, always exploring new ways to do things, did not run from this challenge! This will be a teaser of what to come in a much longer (and in depth) blog post about how we went about this project!

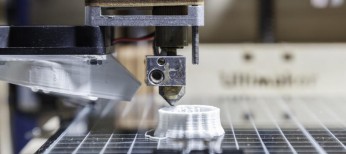

We were given a Hood Scoop that was in need of fiberglass repair but also needed the mounting studs repaired after several decades of neglect and water infiltration. Our original thought was to glass them back to factory shape, but an INTEGRIST had a different idea, after helping his son with a spoiler project, he thought to 3D print & re-stud the mounting supports. This would involve using a CAD program to model up the correct shape and then 3D print with ABS to ensure heat tolerance, but would provide a near-factory (albeit hard to tell) solution. So we got to work taking measurements and 3D printing test pieces. We’re going to leave this right here with a pic, and stay tuned for an overview on the final product here in the coming weeks.